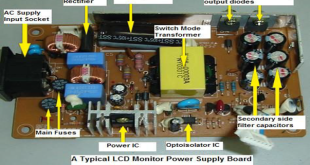

Understanding The Functions Of Switch Mode Power Supply Troubleshooting linear power supply is extremely straightforward …

Read More »-

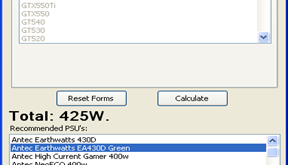

PC Power Supply Calculator

Use this power supply calculator to determine wattage for your PC In order to prevent …

Read More » -

Diagnostic And Repair ATX Power Supply

-

How ATX Power Supply Works

-

ATX Power Supply Pinout

-

Best PC power supply 2017: top PSUs for your PC

-

Basic Troubleshooting Steps

There are some basic troubleshooting steps that you, as an electronic repairer, should pass throw …

Read More » -

Basic Electronics PDF

-

30 Awesome EEE Projects for Electrical Engineers

-

LG LCD TV Repair Training Part2

This is the part 2 of the LG LCD TV repair video guide, learn LCD …

Read More » -

LCD TV Repair Tutorial – LCD TV Parts Overview, Common Symptoms & Solutions – How to Fix LCD TVs

-

LG LCD TV Repair Training Part1

-

Samsung LCD Repair

-

DC/DC Converter using LT1073

1.5V to 5V/12V DC/DC Converter with LT1073 Small 1.5V to 5V or 12V DC/DC converter …

Read More » -

Arduino Watchdog Battery Saver

-

Adjustable Power Supply

-

Build a simple 12 volt power supply

-

Clap Switch Circuit Project