Sometimes, after rains, the air feels moist. The water seems to have suspended in the air. However, in certain AC’s you click some buttons and the atmosphere brightens up. How and why does it all happen? Moisture forms up in the air, resulting in humidity. However, the humidity sensor in your AC picks it up and cleans it up for you. Isn’t that wonderful? Let’s take a look how it does that.

A humidity sensor (or hygrometer) senses, measures and reports both moisture and air temperature. The ratio of moisture in the air to the highest amount of moisture at a particular air temperature is called relative humidity. Relative humidity becomes an important factor, when looking for comfort.

Humidity sensors work by detecting changes that alter electrical currents or temperature in the air.

There are three basic types of humidity sensors:

All three types of sensors monitor minute changes in the atmosphere in order to calculate the humidity in the air. Let us discuss these types in detail:

A capacitive humidity sensor measures relative humidity by placing a thin strip of metal oxide between two electrodes. The metal oxide’s electrical capacity changes with the atmosphere’s relative humidity. Weather, commercial and industries are the major application areas.

The capacitive type sensors are linear and can measure relative humidity from 0% to 100%. The catch here is a complex circuit and regular calibration. However for designers this a lesser hassle over precise measurement and hence these dominate atmospheric and process measurements. These are the only types of full-range relative humidity measuring devices down to 0% relative humidity. This low temperature effect often leads to them being used over wide temperature ranges without active temperature compensation.

Resistive humidity sensors utilize ions in salts to measure the electrical impedance of atoms. As humidity changes, so do the resistance of the electrodes on either side of the salt medium.

Two thermal sensors conduct electricity based upon the humidity of the surrounding air. One sensor is encased in dry nitrogen while the other measures ambient air. The difference between the two measures the humidity.

Tips on Humidity Sensor working

Some parameters for judgement

So once you know what it is, and how it works, the next step probably would be to check its working. And how do you do that? By working through some of the below-mentioned parameters.

Every sensor has its own calibration curve, based on a 9 point system. It basically pitches the pros against the cons of the particular sensor.

It indicates the voltage deviation from the BFSL value and the measured output voltage value, converted to relative humidity.

The measurements often cause the sensor to fall out of sync. However for a sensor to be useful, it has to be provide reliable measurements.

The measurements from a sensor, have to be so that they don’t drift apart. Repeatability is the measurement of drift among measurements of a single quantity.

Response time

Typically, the time taken by a sensor to rise to 66% (rise time) or fall to 33% (fall time) of maximum output voltage, is known as the response time.

Applications of humidity sensors are far and wide

The applications of humidity sensor range far and wide. People with illnesses affected by humidity, monitoring and preventive measure in homes employ humidity sensors. A humidity sensor is also found as part of home heating, ventilating and air conditioning systems (HVAC systems). These are also used in offices, cars, humidors, museums, industrial spaces and greenhouses and are also used in meteorology stations to report and predict weather.

We list out some projects below for reference.

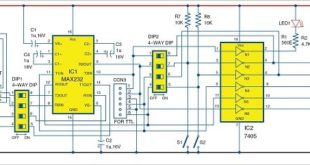

Presented here is a simple humidity indicator and controller. In industries such as textile, the change in moisture content has a direct impact on the properties of fabric, such as tensile strength, elasticity, fibre diameter and friction. Cotton and linen require high relative humidity (RH) levels of around 70-80 per cent, since they are very brittle. Wool requires RH levels of around 65 per cent. While silk requires between 65 and 70 per cent. With this circuit, you can not only monitor humidity levels between 30 and 90 per cent RH but also control it.

The small sniffer device, described in this project, picks up temperature and humidity from inside the fridge and transmits on an RF link to a nearby receiver unit. The receiver unit checks the received code, identifies the right sniffer device and displays live temperature and humidity. Why do we need it you say? We can measure temperature and humidity inside the fridge using a normal temperature-humidity indicator but relative humidity could be inaccurate in that case.

In this article, humidity and temperature information from DHT-11 sensor is analysed graphically on ThingSpeak platform using Arduino MCU and ESP8266 Wi-Fi module.

Presented here is a simple humidity indicator and controller. In industries such as textile, the change in moisture content has a direct impact on the properties of fabric, such as tensile strength, elasticity, fibre diameter and friction. Therefore the process is executed within a permissible humidity environment only. Depending on the type of fabric and the process being undertaken, the requirement of particular humidity level varies. Cotton and linen have to be processed at very high relative humidity (RH) levels of around 70-80 per cent, since they are very brittle. Wool requires RH levels of around 65 per cent. Silk needs to be processed between 65 and 70 per cent. With this circuit, you can not only monitor humidity levels between 30 and 90 per cent RH but also control it.

Got some questions?

You can comment your queries in the comment section given below.

Wanna check out the video on humidity sensor: Working with humidity sensor

A quick guide to humidity sensors in the form of slideshow given below: