Tiny PLC reference design solves the basic design hurdles to implement Industry 4.0

Programmable logic controllers (PLC) are one of the essential components of most industrial control and factory automation systems. As a brain of the factory, a PLC receives and processes data from sensors and machines and uses this data to control a wide range of functions.

However, making PLCs ready for Industry 4.0 is fraught with new challenges. The Industry 4.0 basic premise is that an ever-increasing amount of manufacturing data is collected and shared using a myriad of smart, connected sensors, to reduce production downtime and offer greater ability to predict and adjust to changes. Designing smaller, yet powerful PLCs and moving them closer to the process or assembly line that they control adds flexibility to a complex assembly line, provides low-latency control, alleviate the main PLC’s processing requirements and improves manufacturing throughput.

To achieve the promise of Industry 4.0, today’s PLCs should be compact and be capable of operating in extreme environmental conditions, provide energy efficient operation to ensure fanless operation, and be powerful enough to manage a full suite of IO’s to control a manufacturing node or piece of equipment.

PLCs will also have to support various I/O protocols, including newer ones such as the IO-Link standard which is simple to use and implement, and capable of providing intelligent data from smart sensors.

Achieving these attributes will allow the full power of a standalone PLC to be integrated into the machines on the factory floor providing operational redundancy and integrating an “Adaptive Manufacturing” capability.

Pocket-IO PLC maximizes productivity for IIoT

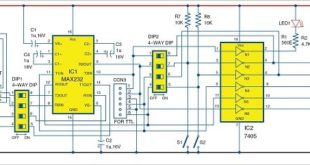

Maxim Integrated has developed a tiny, open-source PLC reference design – the Pocket IO – that meets these challenges.

READ

Making A Small “CFL Lamp Ballast”!

The design offers real-time intelligence to quickly and effectively make decisions, adaptive manufacturing to avoid potential downtime, and distributed control to provide redundancy.

The fanless PLC reference design takes up less than 10 cubic inches of space and packs the capability to communicate to an array of Analog and Digital sensors, make a decision on this information, and translate this into an action by driving a relay, opening/closing a valve, or controlling a motor.

Key features of the PLC:

- The design takes up less than 10 cubic inches of space, the PLC offers a combination of 30 IOs to interface with a vast array of sensors. These IOs include analog input, analog output, digital input, digital output, IO-link, and motion control featuring robust functionality and diagnostic capabilities.

- It is compact, portable and can operate off standard AAA / AA (> 2hr of operation) or LiFePO4 rechargeable batteries (> 8hrs of operation).

- The PLC’s operation can be controlled from iPhones or iPads, acting as HMIs.

- The PLC iimproves reliability and provide diagnostics that will help to cut maintenance costs and increase uptime.

- Designers can quickly create innovative industrial control systems that can be controlled by an iPad or iPhone using the power of Intel’s Edison and the Arduino Sketch open-source IDE programming tools.

Click here for the reference design.

This content was originally published here.